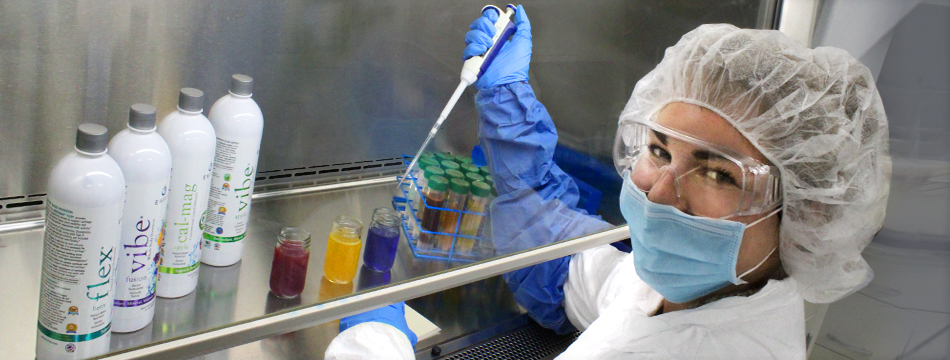

R & D Manufacturing

We know what’s in the products is important to you. But oftentimes there’s less thought given to how the product is made. the process or environment used in making them. The process and environment can make all the difference between two products that appear to be the same, but are actually vastly different.

We know what’s in the products is important to you. But oftentimes there’s less thought given to how the product is made. the process or environment used in making them. The process and environment can make all the difference between two products that appear to be the same, but are actually vastly different.

Superior manufacturing is the cornerstone of Eniva nutraceutical products.

First, we choose to be the manufacturer of our own products so we can ultimately control the quality. We manage the process, from the materials used in the product, all the way to the testing of the finished goods. We match the “fingerprint” of all incoming raw materials to authenticate that what is going into our products is correct and according to our standards. We test the product as we make it, and we test as we bottle it. You can be assured the product in you receive is safe and authentic. We take seriously the fact you consume our products … we consume them, too. Their quality and safety is our top goal.

Second, Eniva has been a registered Food and Drug Administration establishment for more than a decade. We were voluntary registrants even before it became mandatory. Our products are produced in compliance with current Good Manufacturing Practices (GMPs) set forth by the FDA. Our products are regulated under the federal DSHEA and FFDCA statutes, legislation ensuring the safety and authenticity of dietary supplements. We are also regularly inspected by the Minnesota Department of Agriculture.

Third, the methodology counts. We manufacture our products in ways that give the best nutritional profile. We use a whole food matrix approach to using nutrients that are naturally synergistic – the way they are found in nature. We choose to use only natural ingredients. We focus on liquid, because we want to help your body get the nutrients the best way possible, and to actually use them. Traditional supplements in tablet and pill form just don’t cut it – liquid is what you body wants and liquid is what we’ve designed for years. We pioneered the concept of “pre-digested nutrition” years ago, and we still lead the technology behind it.

Third, the methodology counts. We manufacture our products in ways that give the best nutritional profile. We use a whole food matrix approach to using nutrients that are naturally synergistic – the way they are found in nature. We choose to use only natural ingredients. We focus on liquid, because we want to help your body get the nutrients the best way possible, and to actually use them. Traditional supplements in tablet and pill form just don’t cut it – liquid is what you body wants and liquid is what we’ve designed for years. We pioneered the concept of “pre-digested nutrition” years ago, and we still lead the technology behind it.

We don't pasteurize or irradiate our supplements, like many other companies do. Pasteurizing and irradiating diminish the nutrient integrity; we find other ways to keep our products as fresh as possible. And we intentionally make smaller, more frequent batches so the product is as fresh as it can be when you consume it.

Over the years, we’ve believed people can achieve the right outcomes with the right ingredients, in the right form. It’s all about what’s in the product and how it’s made. And our results prove it.

Eniva Health is proud to bring you world class dietary supplements manufactured in our GMP Certified manufacturing facility.

GMP Registered and Certified

Dietary Supplement Manufacturing Facility

The Eniva Health facility has been assessed and is in compliance with:

• Good Manufacturing Practices (GMPs) provide a system of processes, procedures and documentation to assure a product has the identity, strength, composition, quality and purity that appear on its label. These GMP requirements are maintained in accordance with the FDA’s 21 CFR part 111.

• Regular on-site inspections are conducted with the FDA and MN Department of Agriculture of the Eniva Health manufacturing facilities. In addition, regular re-testing of products are done to ensure that they continue to meet the same high standards required to maintain certification over time.